+86 137 0938 2367

+86 137 0938 2367

Nov. 30, 2023

Henglong have established a technology research and development center, which includes four research and development departments: Product R&D Department, Mold Department, Automation Department, and Injection New Material R&D Department. These departments are responsible for researching and developing new products, new processes, new equipment, and new materials in the fields of in-mold labeling injection products, thin-wall injection molds, automation equipment, and injection materials. The center is equipped with a comprehensive laboratory, a microbiology laboratory, and other testing centers totaling over 200 square meters, as well as a comprehensive workshop spanning over 1000 square meters. Advanced research and development instruments and equipment, such as CNC machine tools, surface grinders, universal rocker milling machines, precision grinding machines, coordinate measuring machines, and precision CNC engraving machines, are available. Currently, we have 28 R&D technicians in the company.

We have established a technology innovation team, which regularly collects information on new technologies, new materials, new processes, new standards, and new products in the industry through website queries, participation in relevant exhibitions, and purchaveing the latest products from the market. The team then conducts technology evaluation and discussions, absorbs and transforms the collected information, combines it with the company's own relevant technologies, and carries out further innovation. This ultimately enables the company to maintain a leading position in the industry's overall technological level and provide sufficient basis for strategic decision-making. We have also established a comprehensive technology information collection system, including the establishment of an enterprise technology information management system. It have a real-time product and technology information collection platform, which timely obtains information on industry development trends, competitive products, and new technologies, ensuring sensitivity to industry development trends and providing sufficient factual basis for formulating technology plans.

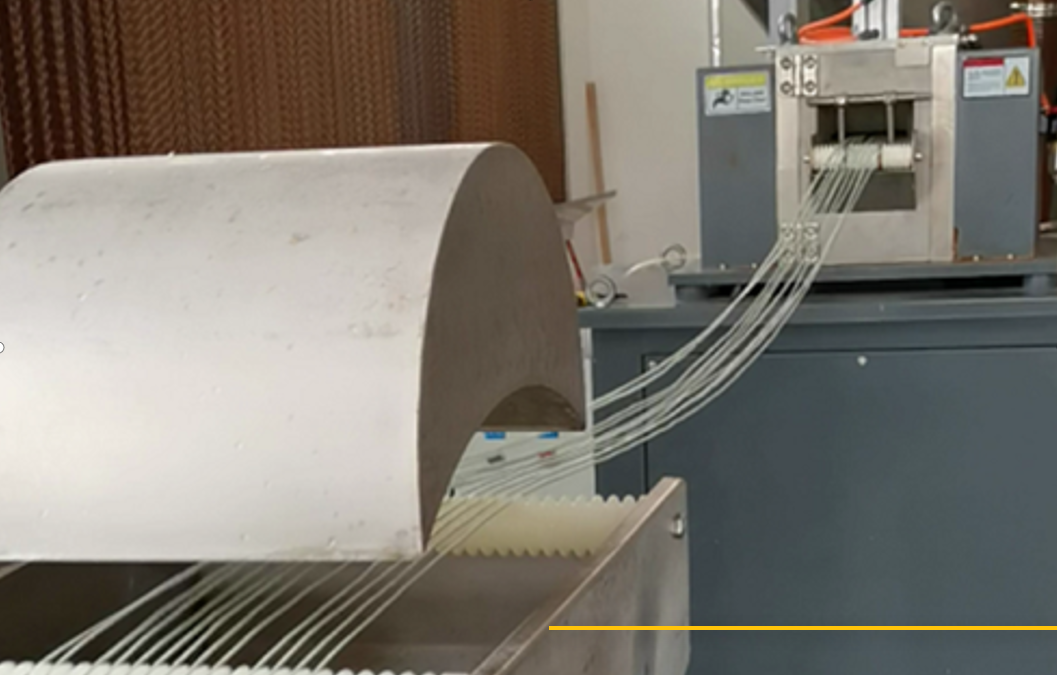

In recent years, we have continuously explored and innovated in the key development project of IML in-mold labeling thin-wall injection containers, including product appearance and structure, mold design and manufacturing, automation introduction, and the development of new plastic materials. We have independently developed various technologies, such as an IML fully automatic production line and its production process, a spoon cup lid injection molding production line and its production process, and a new type of environmentally friendly surface box. These technologies enable efficient labeling and product output operations, ensure the orderly and reliable stacking operations of products on the assembly line, and make the entire production line highly simplified, efficient, and stable. We have the ability to mass-produce and deliver products quickly, bringing greater economic benefits.

We have achieved significant results in high barrier technology, degradable materials, multi-cavity co-molded mold schemes, multi-label in-mold labeling technology, visual inspection, automatic assembly and automatic palletizing, and fully automated production processes through four related R&D departments in the technology center. Over the past three years, more than 100 new IML projects have been developed and put into mass production, with significant achievements and benefits. Henglong have become a supplier to well-known domestic and foreign enterprises such as Nestle, Mondelēz, Lactalis, Subway, Hershey's, Peters, Tiptop and Kroger, ALDI, Coles, Woolworths and has taken a leading position in the IML packaging industry.

Navigation

+86 596 6797 686

+86 137 0938 2367

Longchi Development Zone, Jiaomei Town, Taiwanese Investment Zone, Zhangzhou, Fujian, China