+86 137 0938 2367

+86 137 0938 2367

This 125ml ice cream container is made using In-Mold Labeling (IML) manufacturing technology with eco-friendly Polypropylene material, making it biodegradable.

This 125ml IML plastic ice cream container is a high quality ice cream packaging solution. Features include durable plastic material, beautiful IML printing technology, closed lid. This container can be used to hold 125ml of ice cream or other frozen foods, making it ideal for retail sales or takeaway services. The wholesale minimum order quantity is 140000 sets, which can provide stable supply for your business needs.

| Honokage item no.: | 01-001 |

| Description: | 125ml IML Plastic Ice Cream Container |

| Brimful Volume: | 170ML |

| Serving Capacity: | 125g |

| Material: | Polypropylene (PP) |

| Manufacturing Technology: | IML - In-Mould Labelling |

| Product Dimension: | Φ76*66.1mm |

| Container loading: | 20GP:172, 800sets, 40HQ:437, 400sets |

| Carton QTY: | lid 1800pcs/465*395*415mm/carton, tub 600pcs/ 470*395*365mm/ carton |

| Minimum Order: | 140000 sets |

| Ideal For: | Ice cream, Chocolates, snack, spread, cheese, Sauces, Pets food, Convenience Store, food |

Henglong Plastic is one of the best supplier & exporter of 125ml Ice Cream Container from China. We provide the best quality at the latest price all over China.

Features & Benefits:

Suitable for direct food contact, FDA approval material

Available in transparent, or solid coloured (upon demand)

High-quality decoration alternatives, IML printing, labels can also be supplied premium metallic gold color, the glossy silver, transparent glossy, transparent matte, complex white orange peel, standard matte and glossy.

IML Mold labels scratch resistant, resist humidity and are not afraid of big temperature changes, attractive branding

Round shape plastic rigid tub, Safety Lock, tamper evident lid

Minimum temperature resistance: -40℃

100% Recyclable, environmentally, -friendly helping brand owners meet and exceed their sustainability goals

fast leading time, can save time on preparation for packaging order delivery

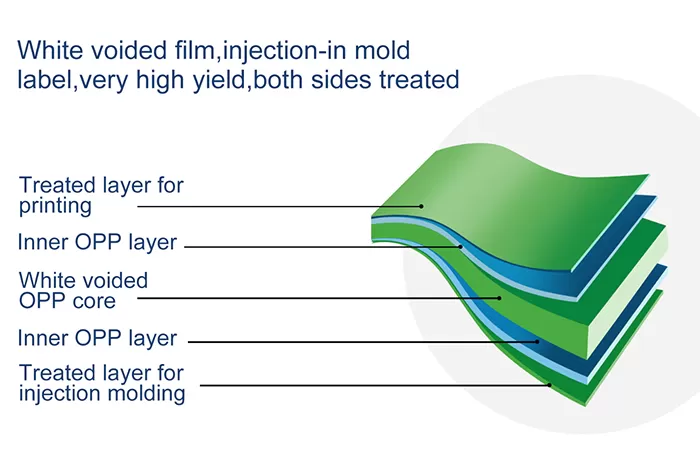

IML main features of packaging

What is in-mould labelling (IML)?

The term “In Mold Labelling” (IML) is a technique where we place pre-printed PP label in a mold and this mold has the shape of the end product, for example yogurt cup,biscuit box or magarine container, ice cream tub packaging. After, we add molten PP to the mold, it melts down with a label and while healing takes the form of the mold. All of this process results in label and packaging becoming into one product.This provides higher quality print and a greater area to enhance shelf appeal as it covers multiple surfaces of a product. There is virtually no limitation on colours or images used – from glossy to matte finishes; one side, all sides and print can even extend over the sides.

Advantage of IML packaging in Honokage

IML container has a better print quality than ordinary container because it allows to decorate all sides. It is also the best way to decorate freezer container or ice cream containers because mold labels scratch resistant, resist humidity and are not afraid of big temperature changes. IML process is environmentally friendly because labelling and packaging are consisted of the same material and also can be fully recycled. IML is also popular because it can be decorated in many different style printing ,such as the premium metallic gold color, the glossy silver, transparent glossy, transparent matte , complex white orange peel , standard matte and glossy. , That's why more and more companies are choosing IML because it really has better quality, it is environmentally-friendly and has a bigger choice of materials.

Benefits of IML

In-mold labelling, in comparison to glue-applied labels, require no glue during application as they are fused directly to the plastic container at the molding step. You get a finished plastic packaging that is resistant, durable, and attractive.

By selecting an in-mold labelling, rather than a shrink sleeve label, no need the secondary operations during production, so could save the manufacture cost and short the leading time, and reduce the amount of waste when launching your production lines.

In mold labelling technique esures high resolutions images, with up to 10 colors choice, the label material is humidity resistant and temperature stable.A great choice for the frozen and refrigerated products, such as the ice cream tubs.

The in mold labelling material, they are also 100% recycled, either directly during the manufacturing process or after consumer use. There is only one material used in production, no need to handle two material differently in the recycling process.

In mold labelling is also being used to enhance the physical properties of products by embedding oxygen or UV protective sections into packaging to improve the shelf-life.

The in-mold labelling technology is popular in sectors where safety is particularly important for health and safety food packaging.

If you are interested in our company

With the continuous expansion of the IML packagings production line, we built the second GMP workshop 1000 square meters with another 12 sets high speed injection machine with full aumatic systems. Awarded National high-tech enterprise.

TAGS

Navigation

+86 596 6797 686

+86 137 0938 2367

Longchi Development Zone, Jiaomei Town, Taiwanese Investment Zone, Zhangzhou, Fujian, China