+86 137 0938 2367

+86 137 0938 2367

Sep. 14, 2023

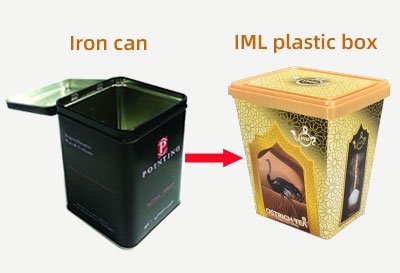

In today's competitive market, packaging plays a pivotal role in brand recognition and consumer appeal. As businesses strive to enhance the aesthetics and functionality of their products, many are turning to Injection Molded In-Mold Labeling (IML) box packaging as a superior alternative to traditional iron can packaging. This article will guide you through the process of upgrading your current iron can packaging to IML container packaging, highlighting the benefits and steps involved.

The Advantages of IML containers Packaging

Before delving into the upgrade process, it's crucial to understand why IML box packaging is gaining popularity in various industries. Here are some key advantages:

1. Enhanced Visual Appeal: IML allows for high-resolution, full-color printing, enabling intricate and eye-catching designs that can't be achieved with traditional labels or printing on iron cans.

2. Durability: Injection-molded tubs are more robust and resistant to damage than traditional iron cans, protecting your products during transportation and on the store shelves.

3. Versatility: IML packaging can be customized to various shapes and sizes, accommodating a wide range of products.

4. Sustainability: Many IML materials are recyclable, and the elimination of secondary labels reduces waste and promotes eco-friendliness.

5.Brand Differentiation: IML allows for unique branding opportunities, helping your products stand out in a crowded market.

How Honokage Upgrade the Iron Can to IML Box Packaging

1. Assess Your Current Packaging: Begin by evaluating your existing iron can packaging with our R&D team. Determine the size, shape, and design elements that need to be preserved or modified in your new IML box packaging.

2. Material Selection: Choose an injection-moldable material that suits your product's needs. Common options include plastic polypropylene (PP) and polyethylene (PE) due to their flexibility and durability.

3.Design and Artwork: Work with a skilled graphic designer, like YZY, to create an eye-catching label design. IML offers a high level of customization, so take advantage of this opportunity to reinforce your brand image.

4.Mold Development: Collaborate with Honokage specialized mold manufacturer, to create the injection molds for your IML boxes. These molds will determine the final shape and size of your packaging.

5.Injection Molding: Once the molds are ready, your chosen material is injected into the molds to create the IML boxes. This process requires precision and expertise to ensure consistent quality.

6.Label Integration: During the injection molding process, the labels are fused directly into the packaging, creating a seamless and permanent bond.

7.Quality Control: Implement strict quality control measures to ensure that the IML boxes meet your specifications and maintain the highest standards.

8.Testing and Prototyping: Before full-scale production, create prototypes to test the packaging's compatibility with your product and to identify any potential issues.

9.Production Scale-Up: Once you are satisfied with the prototypes, ramp up production to meet your packaging needs.

10.Marketing and Promotion: Highlight the upgrade to plastic IML box packaging in your marketing materials and promotions. Communicate the benefits of the new packaging to your customers.

Upgrading from traditional iron can packaging to Injection Molded In-Mold Labeling (IML) box packaging can provide numerous advantages for your products and brand. The enhanced visual appeal, durability, versatility, and sustainability of IML packaging can help your products stand out in the market and attract more customers. By following the steps outlined in this article and working with experienced professionals in the field, you can successfully transition to IML packaging and elevate your product presentation to a new level.

Navigation

+86 596 6797 686

+86 137 0938 2367

Longchi Development Zone, Jiaomei Town, Taiwanese Investment Zone, Zhangzhou, Fujian, China